Business Lessons: The Saga of the Missing Bison Liver

We started a supplement company, Catalyst Foods, to produce high quality, nutrient-dense desiccated grass-fed bison liver, in capsules to help people live their healthiest life. While most supplements on the market are made from chemical synthetic materials, liver is like nature’s multivitamin. We had hoped to have the first capsules ready this summer, but there was a slight hiccup. After ordering 330lbs of raw liver to kick-start production, the pallet of liver was lost in transit to the small freeze dryer manufacturer.

Despite this unfortunate event and the temporary cancellation of capsule creation, this product idea has led to something bigger, shifting the vision to building a community – exposure to a carnivore/animal-based diet, organ meats, and bison for optimal health.

The impetus for this journey was, as written here and here, that I had been struggling with digestive problems and skin issues from eczema that made social situations challenging. After changing my diet to carnivore/animal-based, the digestive and skin issues were eliminated. Instead of targeting merely symptoms, the problem’s root causes were addressed, I was more satiated throughout the day, and free of brain fog.

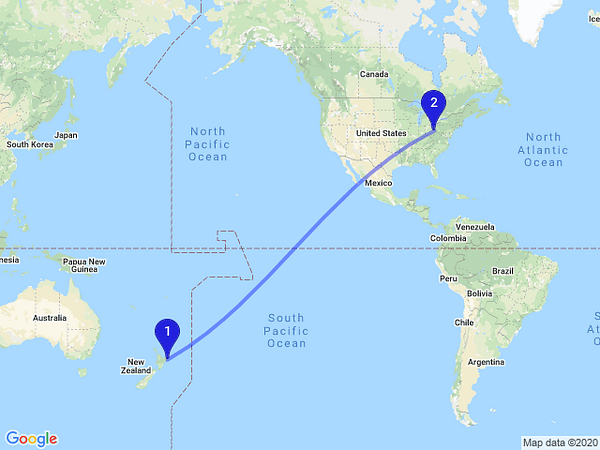

One change I made as part of this diet that helped increase my energy levels was the introduction of desiccated (freeze-dried) beef liver capsules. I wanted to take it a step further though and consume liver that didn’t have to travel across the ocean, as the vast majority of desiccated beef liver comes from New Zealand or Argentina.

The answer to this challenge was bison – proudly American and not domesticated, an animal born and raised in the United States, never given growth hormones, and very rarely administered antibiotics. The difficulty with bison liver capsules, however, was that there weren’t many options on the market, and we weren’t overly impressed with the limited few (few, as in literally three) that we found. So, we decided this might be an opportunity to provide value to like-minded folks out there looking for the highest-quality bison liver capsule.

To kick-off the business plan, we identified the production line as follows:

Bison liver - Purchase raw bison livers from a family-owned bison rancher.

Freeze dry - Ship the livers to a small-quantity freeze dryer.

Third party testing - Send a sample of desiccated bison liver in powder for third party testing for contaminants such as E. coli, lead, and arsenic, among others.

Bottling - If it passed the testing, ship the desiccated bison liver to a nationwide nutrition manufacturer that would do the bottling in a state-of-the-art facility.

We then located a bison rancher that could supply a starting quantity of 330lbs of raw liver. This amount would yield about 495 bottles of desiccated bison liver. Through cold calling and emails to 13 bison ranchers, one rancher in Colorado could supply the quantity needed as well as provide grinding services (a requirement by the freeze-drying company). Securing the supply of the initial good gave us additional momentum to continue to the next stage – locate a freeze dryer.

Finding a freeze dryer who could freeze dry bison liver was challenging. There were not many companies, not all freeze-dried meat, and the Minimum Order Quantities (MOQ) were high. When we contacted a few places such as Oregon Freeze Dry, the largest freeze dryer in North America, their MOQ was 250,000lbs. Our initial order of 330lbs only met .12% of the MOQ. However, we ended up finding a freeze dryer, Apex Lyo, that specialized in small custom orders. In early 2022, we toured their facility near Kansas City, Missouri, a topic for another article. Apex Lyo also connected us with a local third-party food and pharmaceutical testing company in Kansas City.

Next, we contacted 15 different nutritional manufacturers that had the necessary qualifications, such as a registered Food and Drug Administration facility and Good Manufacturing Practice certification. Nearly all companies could not partner with Catalyst Foods, because we did not meet their MOQs, typically as high as 5,000 bottles. However, we were lucky for one company to agree to make the product, custom, since we would be providing the desiccated liver. Normally, the nutritional manufacturer supplies the supplement.

With the bison rancher, freeze dryer, third party tester, and nutritional manufacturer lined up, we thought we had achieved victory – this product could be made and provided to people to help them better meet their daily nutrition needs and achieve higher energy levels.

Once the supply chain was determined, the bison liver was ordered in early 2022 for a total of $1,750. Sold at wholesale, that cost included grinding fees to ground the liver similar to ground bison, and shipping from Denver, Colorado, to Kansas City, Missouri – a few days trip by truck. In a few weeks, the liver was scheduled to arrive frozen from the bison rancher to the freeze dryer via a nationwide shipping company.

However, once the bison livers made its way to Kansas City, there was a mix-up with the delivery date due to the bison rancher scheduling the date one week after we had requested it be delivered, and the freeze dryer could not accept it one week later. As a small business, the freeze dryer did not have capacity until the start of summer, three months away, so the bison livers went back on the truck for the roughly 600-mile journey to Denver for holding in an industrial-sized freezer.

The problem compounded. Thinking the new delivery date was set after calls with the shipping company, when we went to check on the order, the shipping company could not locate the bison livers. The entire pallet of 330lbs of bison liver was lost. One month later, the shipping company called to let us know the pallet was found at a freezer in Pennsylvania and that we needed to confirm that it could be delivered the next day to the freeze dryer in Kansas City. Quite understandably, the freeze dryer could not receive that amount for processing in such a short amount of time.

As a result, we had to make a tough decision and have the shipping company dispose of the livers. The freeze dryer did not have capacity to process until another month or more out, and the cost to store the bison livers made it uneconomical to hold for that long of a time. Additionally, the shipping company said that holding the livers for that long would put them at high risk of being lost again.

Although it may appear we lost $1,750, we see this as the price of tuition, experiential business learning that cannot be taught in any school. And, as we venture closer to a post-COVID world, this is a continued reminder that supply chain logistics will remain crucial.

We were bummed that our first order did not come to fruition as a product, but we know that this venture taught us a lot about small business, and we hope that it helps you reading this article have a better understanding of how your supplements are generally made and/or also offers a business lesson to those of you seeking to bring your own ideas to life. This isn’t the end of the road for Catalyst Foods. We’re going to continue building community, creating (hopefully) helpful content, and taking a moment to pause, re-evaluate, and re-consider our options for product creation.

Have a wonderful Fourth of July! And, please continue supporting your local small businesses and farms that are the lifeblood of this country.

👉If you enjoyed this post, feel free to share it with friends!

Related Articles: